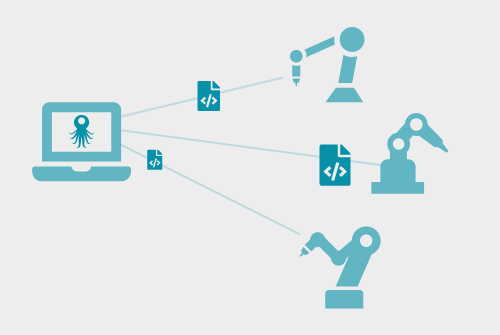

Cut your robot programming time in half

"Without Offline Programming you are talking anything from one to two full-days, depending on complexity. With OCTOPUZ we are down to half a day to a day for an acceptable first off. We have essentially cut the initial programming time in half."